Obliczenia w kalkulatorze są orientacyjne. Bank

przygotuje dla Ciebie ostateczną ofertę, kiedy złożysz wniosek ratalny.

The SOFT SBR treatment plant is used to treat domestic wastewater.

This treatment plant operates using process-based wastewater treatment technology. The treatment process consists of several sequential steps controlled by a computer, which is responsible for aeration, sedimentation, and floatation, as well as pumping the wastewater through a mammoth pump. The treated wastewater can be discharged into the environment.

The tanks are manufactured from high-quality PEHD plastic using the rotomolding method (a plastic molding technique (the rotational molding mold is divided into two or more parts, filled with plastic powder or granulate, then placed in an oven, where the powder turns into a liquid state and thanks to the rotating mold, a monolithic tank is obtained) manufactured in accordance with the PN-EN 12566-3+a2:2013 standard, which guarantees high quality, tightness and durability of the tank.

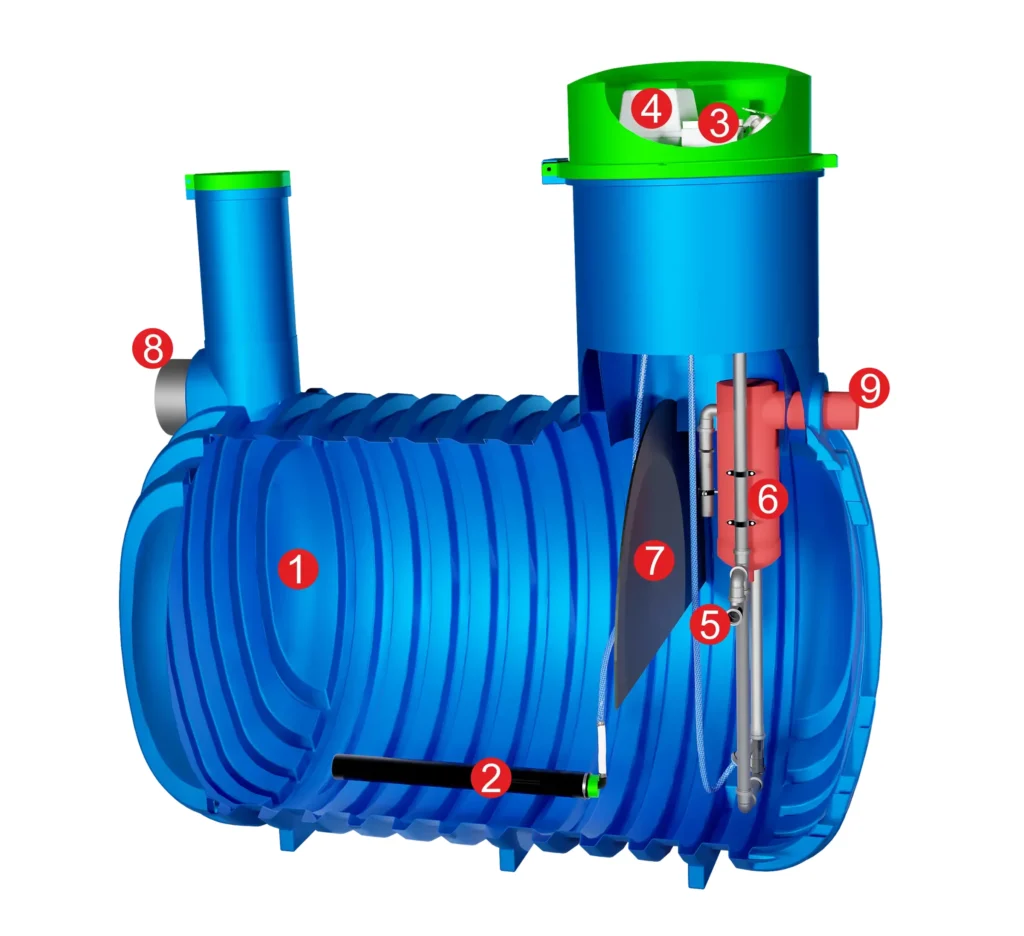

TREATMENT PLANT DIAGRAM:

1. Treatment plant tank – biological reactor

2. Diffuser

3. Wastewater treatment plant controller

4. Aeration blower

5. Mammoth pump

6. Clarification chamber – secondary settling tank

7. Partition

8. Sewage inflow

9. Outflow of treated sewage

The SOFT SBR treatment plant combines two technologies: the simplicity of flow-through solutions and the sequential treatment system found in SBR treatment plants. The SOFT SBR treatment plant operates using batch-based wastewater treatment (SBR). The treatment process consists of several sequential sequences controlled by a control computer that manages aeration, sedimentation, and flotation, as well as wastewater pumping via an airlift pump. The SOFT SBR treatment plant is designed for the treatment of domestic wastewater. Treated wastewater can be discharged into the environment.

Wastewater treatment at SOFT SBR takes place in three stages:

Phase 1 – The wastewater is aerated using a diffuser, creating activated sludge (bacteria aggregated into flocs) that mixes with subsequent portions of the wastewater. Through a controlled aeration process, the wastewater undergoes treatment.

Phase 2 – The controller turns off aeration to allow the wastewater to “settle.” A separation process occurs in the tank. Pollutants lighter than water float to the surface, while heavier pollutants sink to the bottom, creating a layer of sediment.

Phase 3 – In this stage, the pump discharges the treated wastewater from the tank into the infiltration system. The system is designed to eliminate any substances floating on the surface or bottom, only the treated wastewater contained between these layers.

Advantages of the SOFT SBR treatment plant:

– heavily ribbed construction guarantees resistance to ground forces

– small dimensions

– uniform and stable wastewater treatment thanks to which we achieve a higher reduction of pollutants contained in wastewater

– no addition of biopreparations

– low electricity consumption

– installation in difficult ground conditions

– removal of sludge once every 12-24 months

– does not emit unpleasant odors like a traditional cesspool

– 30-year warranty

The treatment plant includes:

– Metria Soft SBR treatment plant tank

– Controller housing with control unit and cover

– Extension

DN 600 H-0,5m

The treatment plant with a 36m drainage system includes:

– Gray PVC pipe DN 110, 1m – 6 pcs.

– Distribution manhole DN 400, H-0.7m or DN 400, H-0.5m or DN 400, H-1.1m – 1 pc.

– PVC elbow DN 110 87 ° gray – 5 pcs.

– PVC drainage pipes DN 110 gray 2m – 18 pcs.

– Vent pipe – 3 pcs.

– Geotextile width 0.5m – 37mb

Treatment plant with 150L tunnel infiltration system includes:

– Gray PVC pipe DN 110, 1m – 3 pcs.

– Distribution manhole DN 400, H-0.7m – 1 pc.

– Gray PVC elbow DN 110, 87° – 1 pc.

– 150L drainage tunnels – 6 pcs.

– PVC drainage pipes DN 110 gray 2m – 3 pcs.

– Ventilation chimney – 1 pc

– Geotextile 2m wide – 6m

The 300l tunnel infiltration treatment plant includes:

– Gray PVC pipe DN 110, 1m – 3 pcs.

– Distribution manhole DN 400, H-0.7m – 1 pc.

– Gray PVC elbow DN 110, 87° – 1 pc.

– 300L drainage tunnels – 4 pcs.

– Ventilation chimney – 1 pc

– Geotextile 2m wide – 6m

Treatment plant with soakaway pit includes:

– Absorbent well DN 600 H-1m perforated with side drainage holes

– DN 600 cover in green color

– Geotextile 2m x 2m

Capacity: 2000L

Number of inhabitants: 4 people

Length: 1600mm

Width: 1400mm

Height: 1600mm

Height to inlet: 1370mm

Height to outlet: 1310mm

Inlet diameter: 160mm

Outlet diameter: 110mm

Diameter of the large manhole: 615mm

Diameter of the small hatch: 245mm

Tank weight: 115 kg

Risers for the tank are available:

– DN 200, height 50 cm and 100 cm

– DN 600 height 50 cm and 100 cm

For safe operation of the device, a fuse box must be installed.

The tank has a CE ITB Certificate, a shortened installation manual, and guidelines for assembly and operation.

Installation on the premises throughout the country by professional teams of installers – agreed upon individually.

Do you have questions? Call us, and we’ll advise you on the best solution for you.

© Xymen 2023. Wszelkie prawa zastrzeżone

Projekt i realizacja: www.wertui.pl