Biological Treatment Plants

Biological wastewater treatment plants find their application everywhere where there is no possibility of connecting to collective sewerage. Thanks to their construction, they ensure a high degree of pollution reduction, which translates into the compactness of the entire installation. Low pollution indicators also mean long system life – some treatment plants have been operating for over 40 years!

Despite the initial, seemingly high investment costs, we can count on huge savings in time and money, thanks to simple and cheap operation.

At the same time, biological treatment plants are beginning to displace traditional septic tanks and putrefying settlers with drainage (ecological treatment plants) from the market, because with proper operation and regular service, we get a device that can work trouble-free for even several decades!

Biological Treatment Plant vs. Ecological Treatment Plant

Your plot doesn’t have a sewerage connection, and the vision of regular visits from a sewage truck doesn’t necessarily fit into your vision of life in a house? An ideal solution may be using a domestic treatment plant. Biological and ecological treatment plants are available on the market, their names sound similar, but are they the same?

biological treatment plant requires less space than ecological

water produced during the operation of a biological treatment plant can be reused, for example for watering plants, in ecological treatment plants this is almost impossible

the treatment process in a biological treatment plant takes place in one tank, while in an ecological treatment plant in two separate containers

The Xymen store offer includes various sizes of treatment plants: 2000l, 2500l, 3000l, 3500l, 4000l, 4750l. This makes it possible to select an appropriate system for households of different sizes.

How Does a Biological Treatment Plant Work and What are the Types of Biological Treatment Plants?

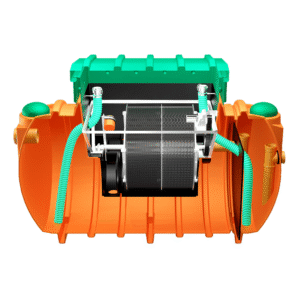

models with activated sludge, the tank is divided into three chambers: primary settler, aeration, secondary settler. Wastewater passes sequentially through all chambers. Activated sludge, i.e., floating aerobic microorganisms, decompose material into sludge and supernatant liquid. Proper functioning of microorganisms is ensured by the aeration chamber. Anaerobic sludge settles and is pumped to the third chamber. Then recirculation occurs, i.e., transfer of sludge from the secondary settler chamber to the primary settler chamber, which allows for more efficient system operation. Material that does not decompose is periodically removed from the treatment plant. The supernatant liquid is led to an absorption well or receiver and can be reused.

models with biological bed, the tank is divided into two chambers: septic tank, tank with aerated biological bed, consisting of PVC crystals, stones and polyethylene mesh. A bacterial biofilm develops on the bed surface. Bacteria feed on sewage compounds, which simultaneously purifies them. Wastewater repeatedly passes through both chambers until it is purified and can be discharged to water devices, soil or surface waters. To avoid cleaning the bed, the system is supplemented with a submerged disc or sprinkler bed. This system does not require the use of biopreparations poured into the toilet.

hybrid models

The exact composition of treatment plants may differ minimally in solutions from different manufacturers.

SBR Technology – Biological Treatment Plants

SBR Technology is based on 4 consecutive stages. The first is filling, wastewater in the first chamber is pre-treated, and all solid substances are retained. The next two stages are aeration and sedimentation. The controller controls the alternation of these phases, ensuring proper operation of the activated sludge. Treated wastewater enters the receiver in the final stage, i.e., surface waters or soil.

Elements distributing wastewater from biological treatment plants and their application

drainage – after preliminary treatment of wastewater in the septic tank, it enters drainage pipes, where treatment is taken over by aerobic bacteria. This system is the simplest solution, and infiltration occurs through precisely cut pipes

tunnels – this solution is an alternative to stone drainage, the tunnel thanks to greater storage volume enables shortening of the drainage system. They discharge wastewater through side perforations.

absorption well – a special tank, shaped like a dome placed on a gravel substrate, wastewater discharge to the ground occurs through its bottom and cracks in the side walls. Gravel serves as a filter and facilitates distribution in the ground.

Biological Treatment Plant Manufacturers

The tightness warranty for selected tanks in our offer is up to 20 years.

In our offer we have treatment plants from companies:

Metria, Polish manufacturer of domestic treatment plants for single-family homes and tanks storing various substances. They create their castings using rotomoulding technology.

Centroplast, Polish manufacturer offering compact wastewater treatment systems for single-family homes, but also hotel centers and farms.

Kingspan, Polish manufacturer offering water and wastewater solutions for both single-family buildings and housing estates

Marseplast

Bamartech, Polish manufacturer offering domestic treatment plant systems at world-class level while maintaining reasonable prices